The exhaust header is an essential component of a vehicle’s exhaust system. It is a set of tubes that connect each cylinder’s exhaust port to a common collector pipe, which then routes the exhaust gases to the catalytic converter. The primary function of the exhaust header is to increase engine performance by reducing exhaust backpressure and increasing the engine’s volumetric efficiency.

The purpose of this article is to provide a comprehensive guide on what an exhaust header is, how it works, the different types of exhaust headers available, and how to install and maintain them. The article aims to educate vehicle owners and enthusiasts on the importance of the exhaust header in enhancing engine performance and reducing emissions.

The content of the article will cover the definition of what is an exhaust header, how it differs from the exhaust manifold, and the advantages of using an exhaust header. It will also delve into the exhaust header’s functionality and its impact on engine performance, the types of exhaust headers available, including short-tube headers, mid-length headers, and long-tube headers. Additionally, the article will offer insights into the installation process, maintenance tips, common issues, and repairs associated with the exhaust header.

Jump to

What is an Exhaust Header?

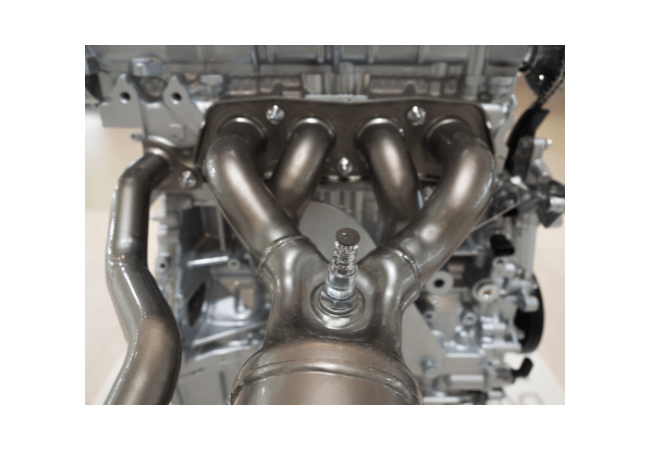

The exhaust header is a component of the exhaust system that replaces the stock exhaust manifold on an engine. The exhaust header comprises a set of individual tubes that connect each cylinder’s exhaust port to a common collector pipe, which then routes the exhaust gases to the catalytic converter. The primary function of the exhaust header is to improve engine performance by reducing exhaust backpressure and increasing the engine’s volumetric efficiency.

The exhaust header differs from the exhaust manifold in terms of design and functionality. While an exhaust manifold is typically a single unit that connects to the engine block, the exhaust header consists of individual tubes that connect to each cylinder. The tubes are designed to be equal in length and diameter to optimize exhaust flow and reduce back pressure. Additionally, unlike the exhaust manifold, which is typically made of cast iron, the exhaust header is usually made of stainless steel or ceramic-coated mild steel to withstand high temperatures and corrosion.

Using an exhaust header has several advantages over using the stock exhaust manifold. The improved exhaust flow provided by the exhaust header results in increased horsepower and torque, better throttle response, and improved fuel efficiency. Additionally, the reduction in backpressure results in a more aggressive engine sound, which many enthusiasts find appealing. The use of high-quality materials in the construction of the exhaust header also makes it more durable and resistant to corrosion, prolonging its lifespan.

How Does an Exhaust Header Work?

The exhaust header works by reducing the resistance that the engine faces when pushing out exhaust gases, resulting in improved engine performance. The header consists of individual tubes, each connected to a specific cylinder’s exhaust port. These tubes are designed to be equal in length and diameter to reduce backpressure and optimize exhaust flow, ensuring that the engine can efficiently push out exhaust gases. By reducing backpressure, the engine can expel exhaust gases more easily, reducing the workload on the engine and improving its efficiency.

The exhaust header’s primary function is to improve engine performance by reducing exhaust backpressure and increasing the engine’s volumetric efficiency. By improving the engine’s ability to expel exhaust gases, the header allows the engine to breathe more freely, leading to an increase in horsepower and torque. Additionally, the header’s design also results in improved throttle response, making the engine more responsive to the driver’s inputs.

The exhaust header’s construction plays a vital role in its performance. Most exhaust headers are made of stainless steel or ceramic-coated mild steel to withstand high temperatures and corrosion. The tubes are mandrel-bent to ensure they remain circular and retain their diameter throughout their length, reducing flow restrictions. The header’s collectors, where the individual tubes merge into a single pipe, are also carefully designed to ensure that exhaust gases from each cylinder flow smoothly and merge without restriction.

The exhaust header has a significant impact on engine performance, improving horsepower and torque while reducing emissions. By improving the engine’s ability to expel exhaust gases, the header reduces the workload on the engine, allowing it to operate more efficiently. The reduction in backpressure also results in a more aggressive engine sound, which many enthusiasts find appealing. Overall, the exhaust header is an essential component of the exhaust system that can significantly enhance engine performance.

Types of Exhaust Headers

Exhaust headers come in various types, with each type designed to cater to specific engine applications. The three most common types of exhaust headers are short-tube headers, mid-length headers, and long-tube headers.

Short-tube headers, also known as shorty headers, are the most basic type of header. They are designed to be a direct replacement for the factory exhaust manifold, with primary tubes that are only slightly longer than the factory manifold. Shorty headers are relatively easy to install and can provide a small increase in horsepower and torque. However, their short length means that they do not provide as significant an improvement in performance as mid-length or long-tube headers.

Mid-length headers are a step up from shorty headers, with primary tubes that are longer than shorty headers but shorter than long-tube headers. They are designed to provide better performance than shorty headers while being easier to install than long-tube headers. Mid-length headers are ideal for street-driven cars that are used for both daily driving and occasional track use.

Long-tube headers are the most significant type of exhaust header, with primary tubes that are significantly longer than shorty or mid-length headers. Long-tube headers are designed to provide the most significant improvement in performance, with gains of up to 25 horsepower and 30 lb-ft of torque possible. However, their longer length means that they are more challenging to install and may not be suitable for street-driven cars that must comply with local emissions regulations.

The choice of exhaust header type depends on the specific engine application and the intended use of the vehicle. Shorty headers are the most basic type, mid-length headers are a step up, while long-tube headers provide the most significant improvement in performance. Choosing the right type of header can significantly enhance engine performance and make driving a more enjoyable experience.

Installation and Maintenance of an Exhaust Header

Installing an exhaust header can be a challenging process, and it is recommended that it be performed by a professional. However, if you have experience working on cars and access to the necessary tools, it is possible to install an exhaust header at home. The installation process involves removing the factory exhaust manifold and replacing it with the new header. Depending on the make and model of the vehicle, some modifications may be necessary to ensure a proper fit. After installation, it is essential to double-check that all bolts and clamps are properly tightened and that there are no exhaust leaks.

Proper maintenance is crucial for ensuring the longevity and performance of an exhaust header. One of the most important maintenance tips is to check for exhaust leaks regularly. Exhaust leaks can cause a variety of problems, including decreased engine performance, increased emissions, and potential safety issues. It is also essential to keep the header clean and free of debris, as dirt and grime can cause corrosion over time. Finally, it is recommended that you follow the manufacturer’s recommendations for cleaning and maintaining the header.

Common issues that can arise with an exhaust header include cracks, leaks, and rust. If you notice any of these issues, it is essential to address them promptly to prevent further damage to the header or other engine components. Depending on the severity of the issue, repairs may involve welding, replacing gaskets or bolts, or even replacing the entire header. Regular maintenance and inspections can help prevent these issues from occurring in the first place, saving you time and money in the long run.

Installing and maintaining an exhaust header requires attention to detail and proper technique. While it is possible to perform the installation and maintenance at home, it is recommended that you consult a professional if you are not experienced in working on cars. Proper maintenance, including regular inspections and cleaning, can help prevent issues from arising and ensure that the header performs optimally for years to come.

Final Thoughts

An exhaust header is an aftermarket exhaust component that replaces the factory exhaust manifold. It is designed to improve engine performance by increasing exhaust flow and reducing back pressure. The exhaust header achieves this by separating the exhaust ports on each cylinder, allowing them to expel exhaust gases more efficiently.

The benefits of using an exhaust header over a factory exhaust manifold include increased horsepower and torque, improved throttle response, and a more aggressive exhaust note. However, it is important to note that installing an exhaust header can be a challenging process, and proper maintenance is essential for ensuring its longevity and performance.

In conclusion, an exhaust header is an excellent upgrade for those looking to improve their vehicle’s performance and sound. However, it is important to weigh the cost and potential installation challenges before making a purchase. If you decide to go ahead with the installation, be sure to follow proper installation and maintenance procedures to ensure the best possible results.

My name is Tom Harris, founder of this blog. I’m a mechanical engineer with 20 years of experience in the automotive industry. I’m here to help you with your vehicle’s problems, easy fixes and share my insights and experience so that you can enjoy your rides more.